ALUMINIUM HEAT TREATMENT

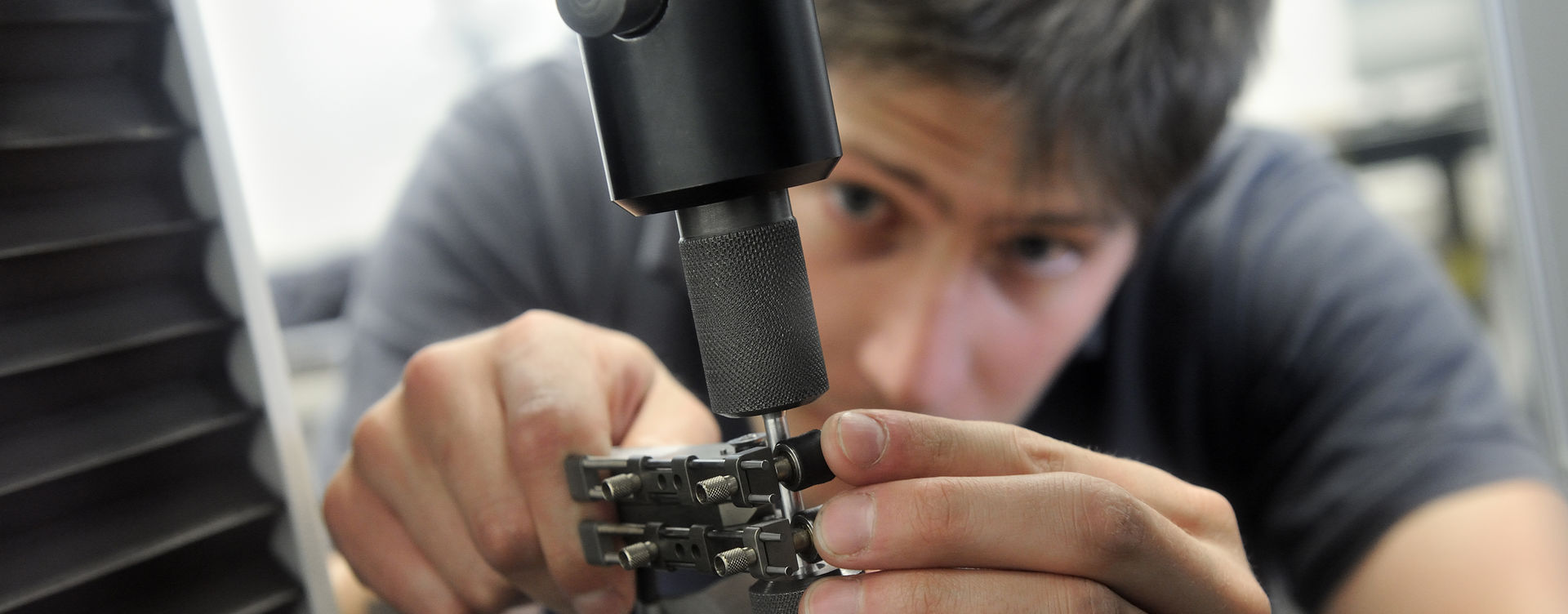

The Hanomag Lohnhärterei Group has been treating aluminum components for over 40 years. We are a series supplier for all automotive manufacturers in Germany and know our way around engine and chassis parts as well as thin-walled structural components.

Thanks to our many years of experience and competent, dedicated employees, we can offer you optimum heat treatment for any aluminum component. Our modern continuous and chamber furnaces use different quenching media. We can offer you water, air and polymer quenching depending on the component.

We will improve your product.