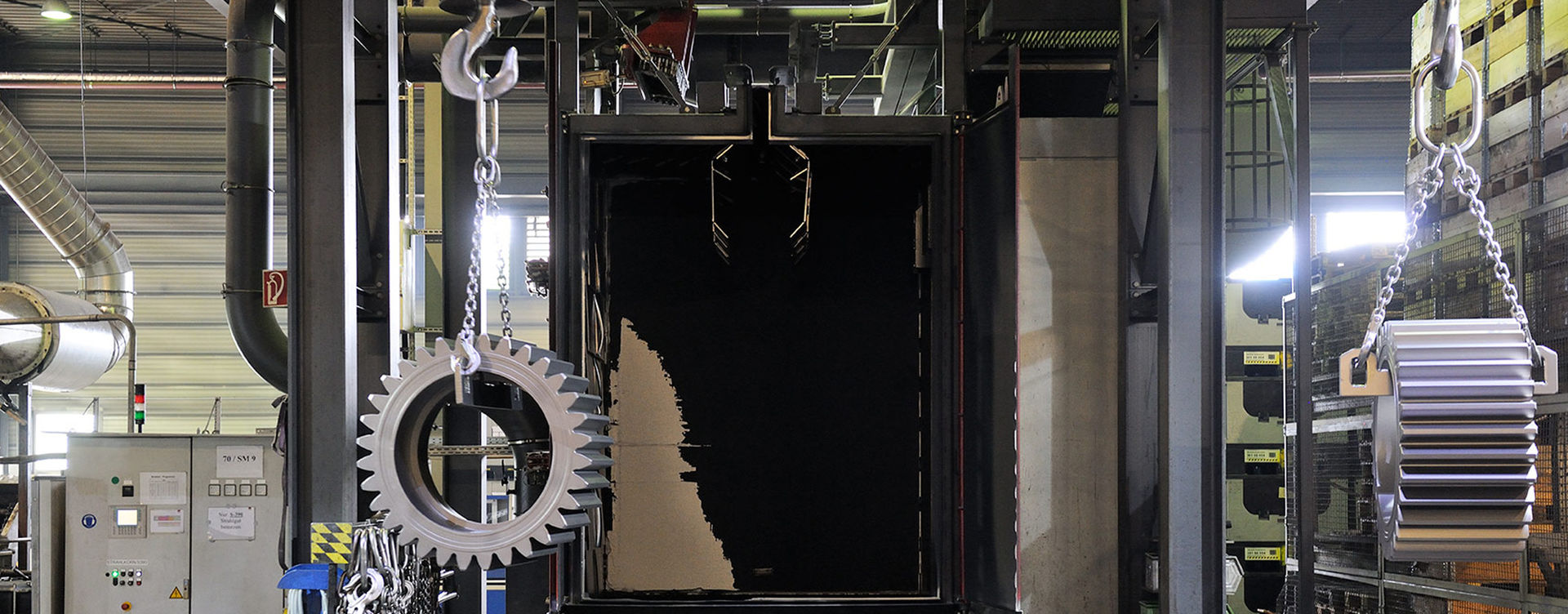

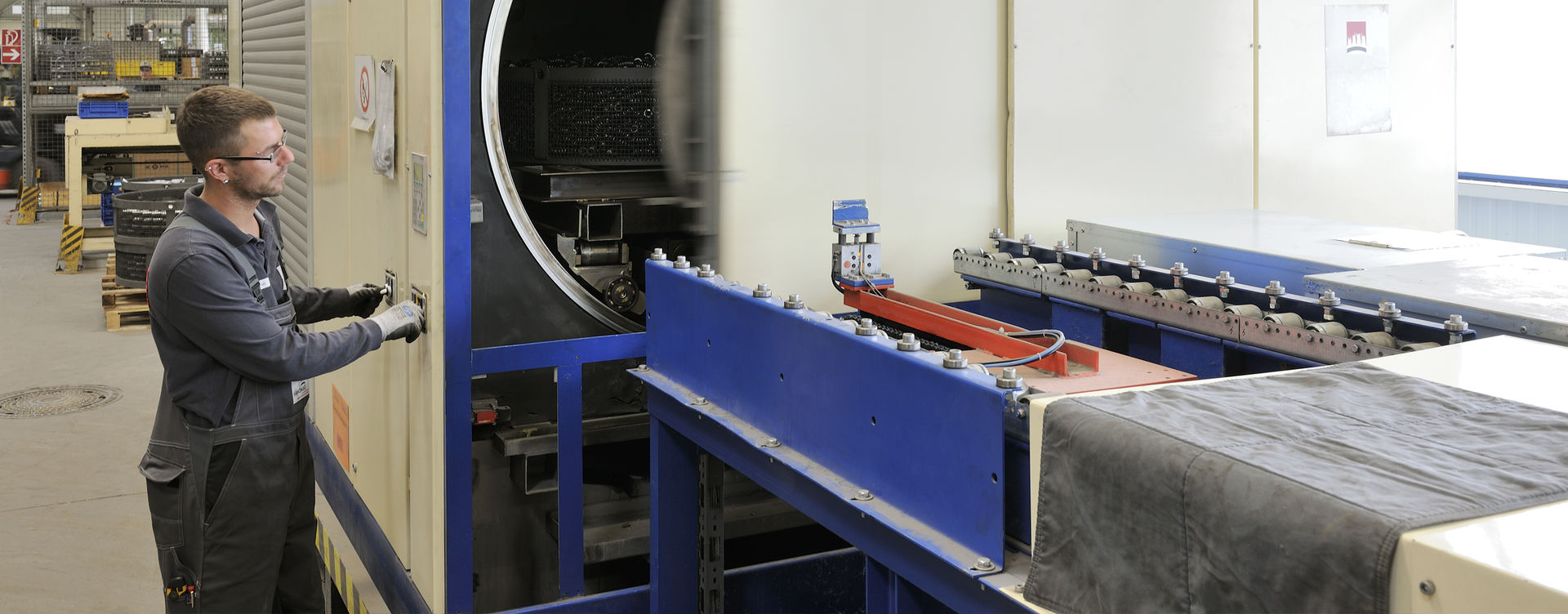

CLEANLINESS AND PRECISION IN THE WHOLE VALUE-ADDED CHAIN

Our production process is matched as best as possible to your component. We will also be pleased to take over process steps for you that go beyond heat treatment itself. We execute upstream and downstream process steps with precision, cleanliness and with a good price-performance ratio.