MECHANICAL PROCESSING - PRECISION WORK ON COMPLEX COMPONENTS

Herbst Zerspanungs- und Messtechnik GmbH performs processing for cylinder heads, engine blocks, subframes, housing components and much more, in varying yearly production quantities, from prototype to series. Thanks to constant investment in replacements and extensions from leading technological suppliers, our machine and plant fleet is state-of-the-art. We work with 4-axis and 5-axis CNC processing centres, are flexible and swift when re-equipping and have access to a large inventory of standard and special tools. Compliance with set values in the µ-range is part of our daily routine.

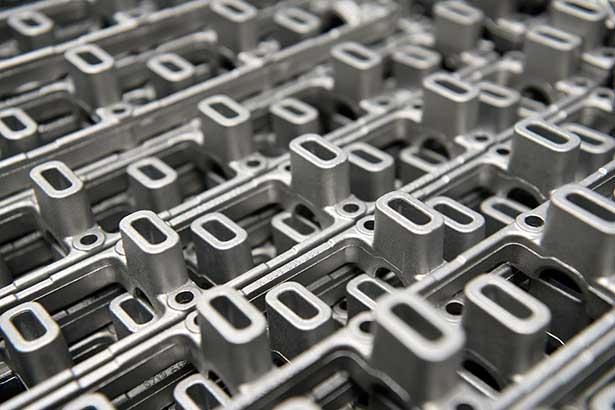

Motor Components

One of the core focuses of Herbst Zerspanungs- und Messtechnik GmbH is the processing of cylinder head covers, oil tanks and motor unit mounts. Over the years, we have realised the most varied products together with our customers. On request, motor components can also be completely assembled by us.

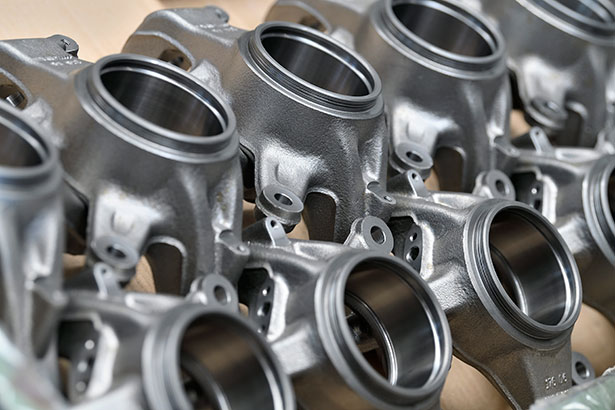

Chassis Parts

Chassis parts have particular safety and precision requirements. Herbst Zerspanungs- und Messtechnik GmbH has years of experience in the processing of steering knuckles, wheel carriers and semi-trailing link axles. We deliver high quality, installation ready finished parts directly to the assembly line on request.

Structural Components

Herbst Zerspanungs- und Messtechnik GmbH recognised the importance of lightweight components early and prepared itself to address these new challenges. As a system supplier, our goal is to use our innovative excellence and experience to offer our customers convincing solutions every time a new need arises.

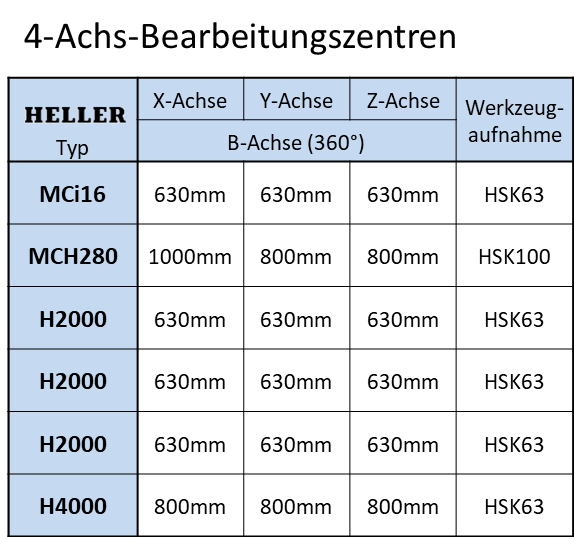

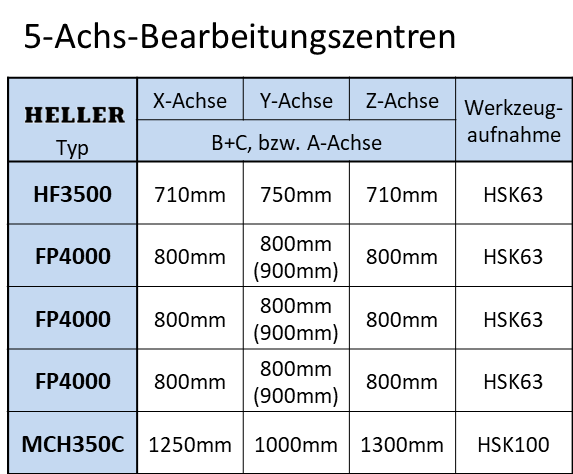

CNC MACHINING

What can we do for you?

We work with 4 and 5-axis CNC processing centres, are flexible and swift when re-equipping and have access to a large inventory of standard and special tools. Compliance with set values in the µ-range is part of our daily routine. An overview of our current manufacturing capabilities; other facilities are being planned.

PROTOTYPE AND SERIAL PRODUCTION DIFFER IN MORE THAN JUST COMPONENT QUANTITY

The development of new components for industry is a demanding process that requires a high level of expertise, flexibility and experienced employees. Rapidity, reliable delivery dates and precision are decisive for the success of a products introduction.

Prototypes

The strengths of Herbst Zerspanungs- und Messtechnik GmbH lies in its production-ready planning and precise preparation of prototypes and small series. We are always in direct communication with our raw parts suppliers; this way, we can guarantee our customers an optimal chain of communication from the development phase through tool construction to finished part manufacture, without losses at the interfaces.

We will support you from the idea to the finished part, with the goal of optimising your product.