Dye penetration testing

(PT- DIN EN ISO 3452)–colloquially “Crack testing”

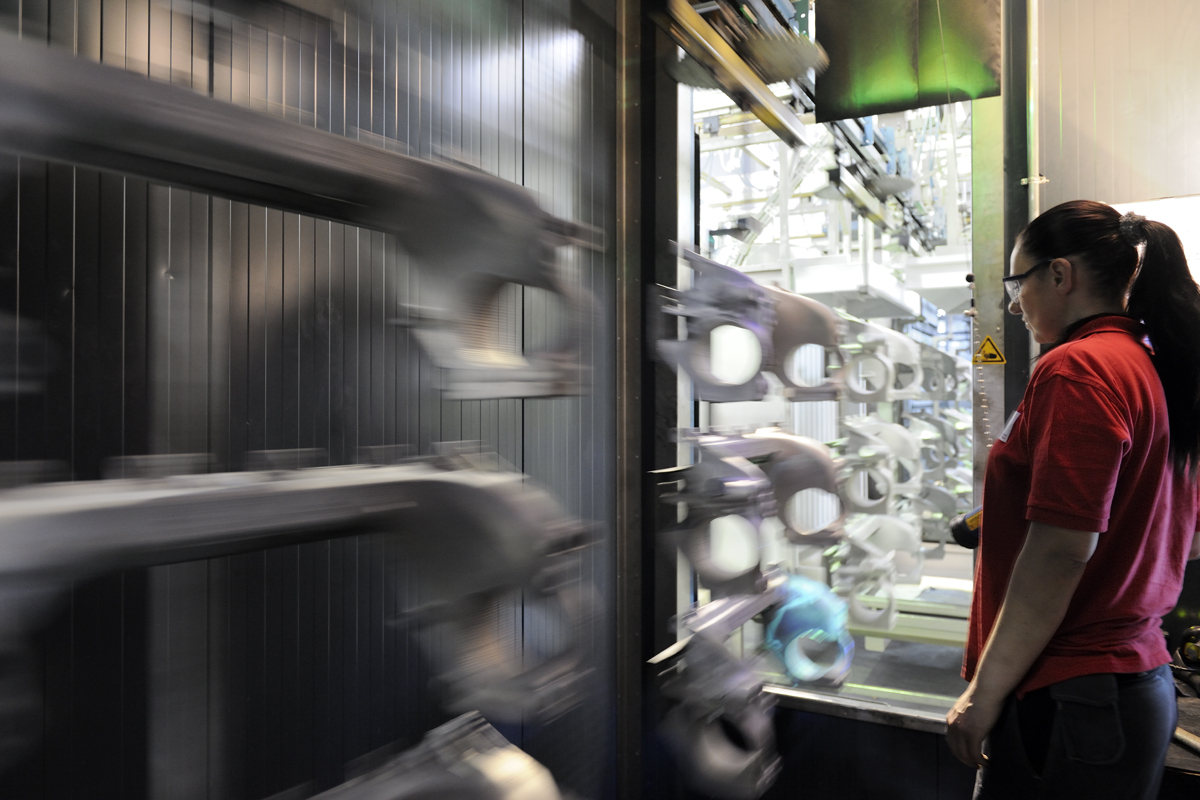

Generally with us, this non-destructive testing procedure is used to test cast aluminium components. In the dye penetration test, the component is cleaned and then immersed in or sprayed with a penetrant. After rinsing, this penetrant is stuck in the surface openings (e.g. pores, cracks). After treating with a developer and subsequent drying, these surface openings can be displayed with the aid of UV light.

We carry out a fluorescent penetration test. With this test process we discover casting defects that can negatively influence the performance characteristics of the component.