SUPPLEMENTARY SERVICES

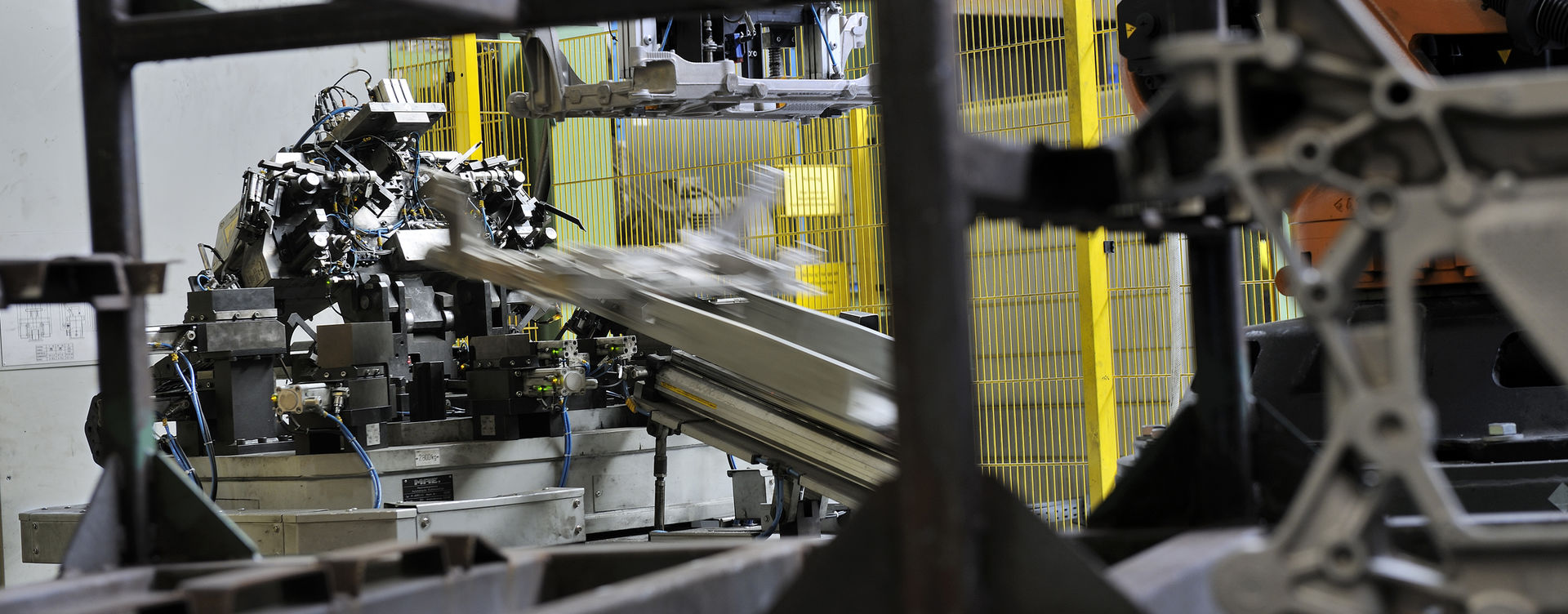

The Hanomag hardening plant offers you the best possible quality and shortest possible lead times as well as the related competitive prices for all downstream processes after casting. It is important to us is to support our customers from the planning stage through to the finished product.

We improve your product!